Download Former workers of the multinational lingerie manufacturer, Triumph International, are now producing thousands of pieces of underwear for sale in Europe.

These workers were laid-off without warning three years ago. In total nearly 2,000 female workers lost their jobs.

Triumph International said it was necessary to lay-off the workers due to a fall in global orders and the restructuring of the company.

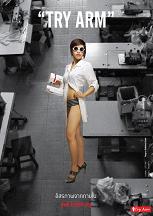

The ex-workers are fighting back and using their skills to produce high quality underwear with a new brand: “Try Arm”.

As Kannikar Petchkaew reports from Samutprakarn, south of Bangkok, for these workers it’s more than just underwear.

Twelve workers are working hard to meet a tight deadline.

Every piece of “Try Arm” underwear must be finished tonight so that it can be distributed to customers across the country.

The factory was started two years ago and the name “Try Arm” is a play on words, poking fun at Triumph International, the company that laid them off.

In 2009, the company said there had been a fall in global orders.

Ma Kulapijit was laid-off along with nearly 2,000 other female workers.

“I worked with Triumph for 19 years. It was a shock when they said that we had to go at such short notice. I was 44 years old and had just bought a house. I have to take care of mother and my own family. At that age, without a higher education, I had nowhere to go. It was very depressing.”

The workers staged protests for three months in front of the factory demanding the company reinstate them, or at the very least pay them fair compensation.

The management refused to talk to them.

Workers took their protest to the Ministry of Labour’s office. They camped outside and made ‘protest underwear’.

Jittra Kotshadej was the former leader of the Triumph Workers Union.

“We want people to know about our struggle. We have the skills to make underwear. We’re making underwear to tell our story.”

A year later, Jittra and 11 other ex-workers created their own brand, “Try Arm”, using a clenched fist as their logo.

“We don’t take donations. If you want to support our fight and if you want to see genuine fair trade for both consumer and producer, support our product.”

For them, “Try Arm” is not just an ordinary factory.

“We have the same system as other businesses. All workers are well-paid. They have holidays, they can ask for leave for their own business and they will also get a bonus almost every year. But what makes us different from others, is that we’re all owners of this small factory. Everyone shares the right to use the machines and other things. I mean, if the business is going to stop someday, everyone will have their own share, of the sewing machines and everything else. It’s not just about earning money. We want to tell everyone about our struggle and to convince other workers that they can do it on their own. Our life does not depend on the factory like we used to believe.”

“Try Arm” started producing just 50 pieces of underwear a day.

Now it has 40 sewing machines and produces thousands of pieces of underwear, bras and swimming suits.

They sell their products cheaply online, between 2 and 17 US dollars – a lot less than the original Triumph products.

“We can wear our own products now. It’s different from the time when we were still working for the factory. We made lots of pieces but we couldn’t afford to buy them because they were very expensive.”

“Try Arm” is now exporting their products to Switzerland – the home of Triumph International.

Jittra believes that “Try Arm” products are a genuine fair-trade brand.

“People who wear our underwear should be proud and say ‘Hey look, I’m wearing “Try Arm”!’ We have made a success here, we survived the lay off from the factory, our families are proud of us. We received support from Unions around the world, while in Thailand only 2 percent of workers are in Unions.

At “Try Arm”, female workers are not just making underwear... they are stitching together a dream for a fairer life.

Comments

Thanks for the comment^^

Glad you like it.Pleas check their site for the products detail.

www.tryarm.blogspot.com

RSS feed for comments to this post.